An efficient HVAC design begins with one crucial step: calculating the correct duct size. Duct sizing is something that can directly affect airflow, energy consumption, and system lifespan, no matter if the job is residential, commercial, or industrial. An oversized duct will mean wasted energy; a duct that is too small produces noise, pressure issues, and possible hot spots in cooling.

This guide lays out the methodology of duct sizing in simple, straightforward, professional terms and explains the key principles of the process.

Why Duct Size Matters

Correct duct sizing ensures:

- Balanced airflow in every room

- Reduced noise, minimal turbulence

- Lower energy consumption

- Efficient heating and cooling performance

- Comfortable indoor temperatures

A well-designed duct system will keep your HVAC equipment from overworking and will increase its lifespan.

Key Factors Used in Duct Size Calculation

Before calculating the size of a duct, several important parameters need to be given due consideration by the engineer:

1. Required Airflow (CFM)

CFM stands for Cubic Feet per Minute and is the amount of air required for each room.

Simple Rule of Thumb:

Bedrooms: 80–120 CFM

Living rooms: 150–250 CFM

Commercial areas: Depends on occupancy and space volume

1. Required Airflow (CFM)

CFM (Cubic Feet per Minute) represents the amount of air needed for each room.

Simple Rule of Thumb:

- Bedrooms: 80–120 CFM

- Living rooms: 150–250 CFM

- Commercial areas: Depends on occupancy and space volume

CFM is the foundation for duct sizing. Without knowing the airflow demand, you cannot begin.

2. Velocity of Airflow (FPM)

Measured in Feet Per Minute, airflow velocity determines how fast air travels inside the duct.

Recommended Velocity:

- Main ducts: 900–1,400 FPM

- Branch ducts: 600–900 FPM

- Residential systems: lower velocity to reduce noise

Correct velocity prevents excessive sound and static pressure problems.

3. Available Static Pressure (ASP)

This is the pressure left in the system to move air through the ducts after accounting for:

- Filters

- Grilles

- Coils

- Dampers

- Duct friction

Lower static pressure requires larger ducts to maintain airflow.

4. Friction Rate (FR)

This is the resistance to airflow inside the duct caused by:

- Length of the duct

- Number of bends

- Fittings and transitions

- Duct material and smoothness

Engineers use friction rate to choose the right duct diameter.

Methods of Calculating Duct Size

There are three commonly used methods:

1. The Equal Friction Method (Most Common)

This method selects duct sizes such that friction loss per meter remains constant throughout the system.

Advantages:

- Easy to design

- Reduces noise

- Suitable for most commercial and residential systems

2. The Velocity Reduction Method

Air velocity is gradually reduced as air moves from the main duct to branch ducts.

Best For:

- Large commercial buildings

- Auditoriums

- High-volume airflow systems

3. Static Regain Method

Used in high-performance HVAC systems, where duct sizes increase in downstream sections to compensate for pressure loss.

Best For:

- Large central plants

- Airports

- Malls

- High-rise buildings

How to Calculate Duct Size (Simplified Steps)

Step 1: Determine Required CFM

Example:

Room requires 200 CFM

Step 2: Decide Air Velocity

Choose:

Residential: 600–900 FPM

Commercial: 800–1,200 FPM

Example:

Velocity = 800 FPM

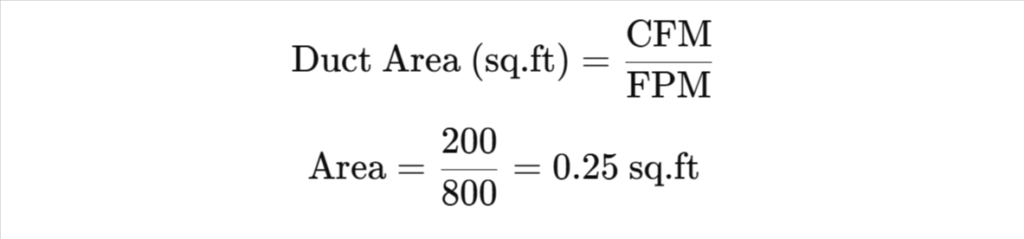

Step 3: Use Formula to Find Duct Area

Step 4: Convert Area to Actual Duct Size

A common duct size close to 0.25 sq.ft cross-section:

- 8″ × 6″

- Round duct of approx. 7″ diameter

HVAC engineers use duct calculators, charts, or software to convert area to exact size.

Tools Used for Duct Sizing

- Ductulator (manual wheel calculator)

- SMACNA tables

- ASHRAE guidelines

- HVAC design software (HAP, Carrier E20, Elite Software)

These ensure accuracy and compliance with industry standards.

Conclusion

Proper duct sizing is essential for designing a comfortable, efficient, and long-lasting HVAC system. By understanding airflow requirements, static pressure, friction rate, and velocity, you can determine the ideal duct dimensions for any project.

If you require factory-fabricated ducts, ready-made ducts, or complete HVAC ducting solutions, Smart Ducts provides accurate engineering, superior quality, and professional installation services.